-

(477) 873-9338

-

ventas@maquinariaparaplastico.comventas@maquinariaparaplastico.com

-

+52 (477) 873-9338+52 (477) 873-9338

Plastics Recycling

We Manufacture Machinery For Plastic Recycling

Turnkey projects! clients and purchase of material insured in advance! in addition to being manufacturers, we also recycle and have all the experience to ensure the success of your business!

Other types of plastics that you can also process

HDPE and PP

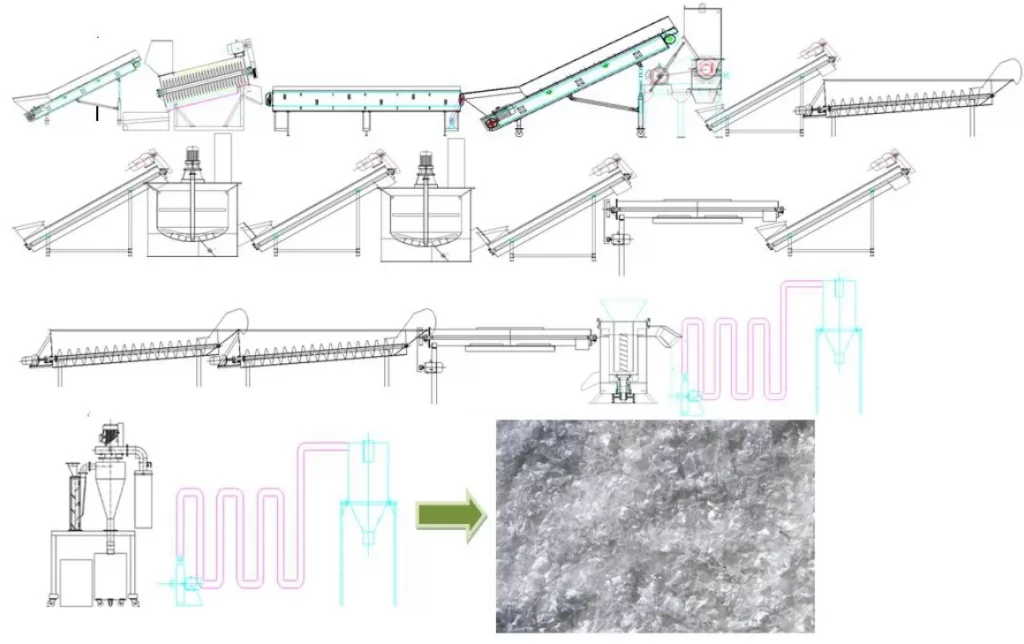

Universal Washing line for pet

Consolidated as the leading Mexican company dedicated to the manufacture of machinery for the transformation and recycling of plastics.

Our commitment is not only to produce high-quality products, but also to continue researching the development of new high-tech materials to help reduce solid contaminants.

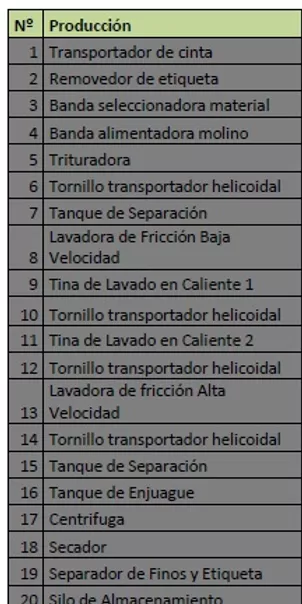

Our recycling lines include units for the grinding, washing and drying of post-industrial and post-consumer PET material with capacities of 500, 1,000 and 2,000 kg/hr, which we offer our customers at very competitive prices while maintaining a high level of quality. .

We have the knowledge, experience and cutting-edge technology with which we develop fully automated process lines controlled by PLC linked to an internet database where production levels can be seen in real time. The information collected throughout the day from the start and/or shutdown of the system can be linked to a mobile device (ipad, iphone or via sms) in order to have total control of what happens in the plant.

The line is modular and versatile in its entirety, offering the option of being able to increase complementary processes to production through additional units or modules in order to be able to adjust or comply with certain parameters required in the quality of the final product.

All the components of the line are manufactured with the highest quality materials using industrial accessories from world-renowned brands (FESTO, VICKERS, SIEMENS, etc.) with which we guarantee the reliability of our lines, offering strong and very resistant units.

Machinery

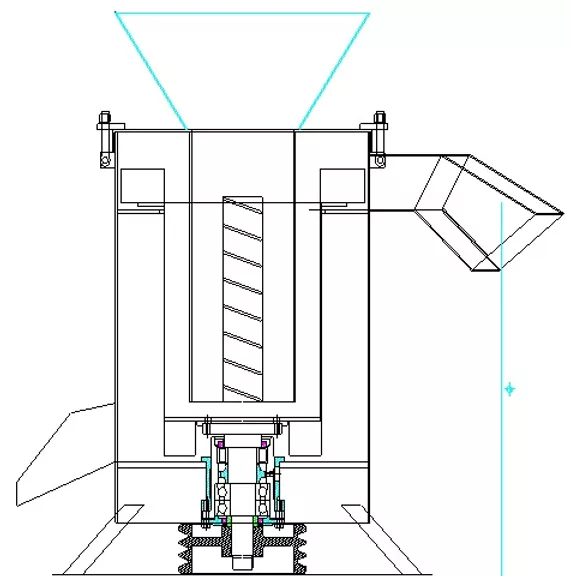

BELT CONVEYOR

UNLABELING MACHINE

SELECTION BAND

FEED CONVEYOR

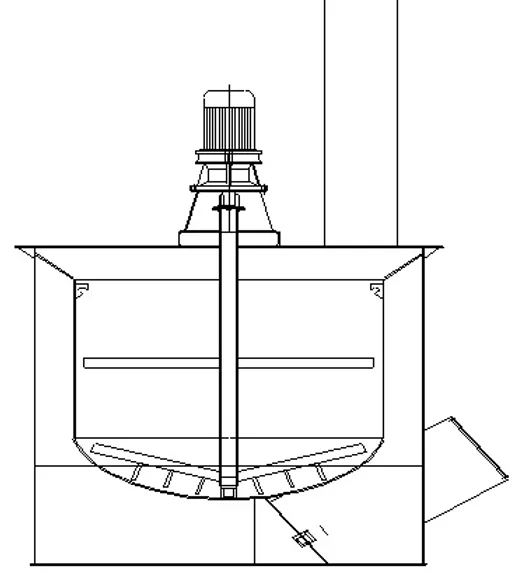

SPEED WASHER

FLOATING WASHER

HELICAL TRANSPORTATION

DEWATERING MACHINE

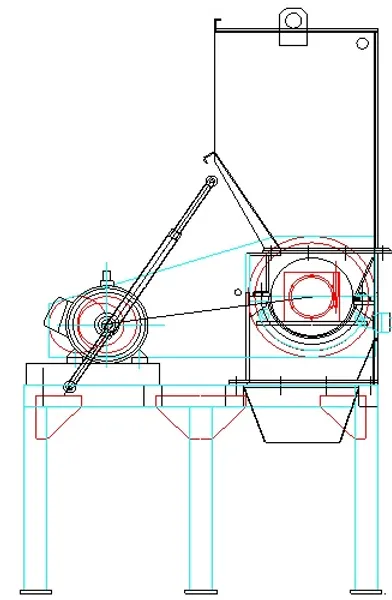

CRUSHER MILL

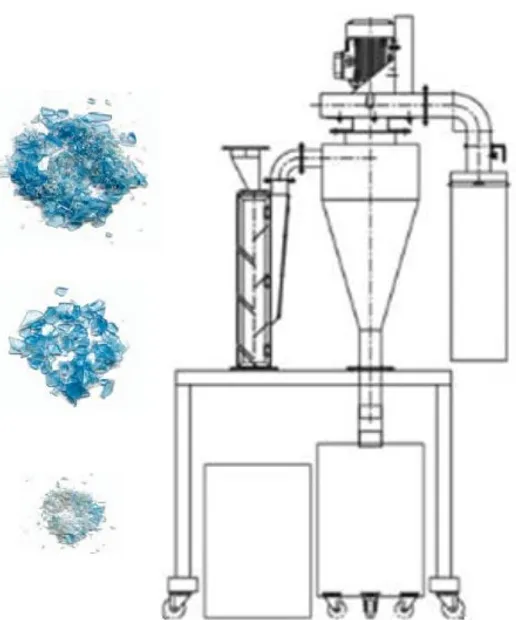

FINE SEPARATOR

STEAM WASHER

DEWATERING MACHINE

Quality Modules B-B (Bottle-Bottle)

The Equipment May Vary Depending On The Degree Of Cleaning Required.

IMPORTANT POINTS TO CONSIDER:

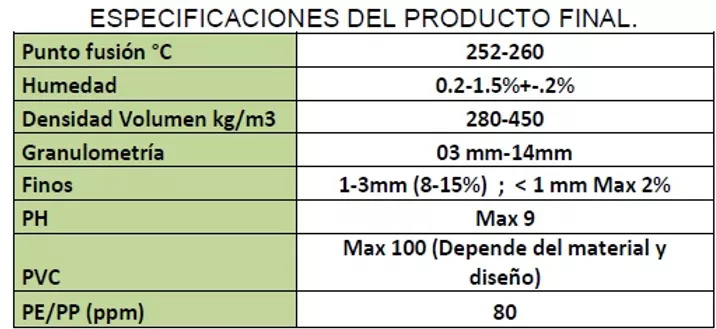

To obtain a quality product and high added value in the market, suitable for the textile industry in the manufacture of polyester fiber or for thermoforming plates, the moisture factor is, which should not exceed 1% and a proportion not greater at 100ppm in labels in the total of your load. we have the experience to develop turnkey projects in order to guarantee a prompt return on your investment.

Warranty. : 12 MONTHS

a) The machinery will be installed and its perfect operation will be tested along the entire line and in each of its modules.

b) The one-year warranty covers all manufacturing defects that may arise as a result of normal use of the machinery.

It does not cover other problems, including those that may arise due to maintenance or incorrect and improper use of the equipment.

The warranty for motors, electrical parts and accessories and in general for all electrical material is 12 months as long as the equipment is properly protected against voltage fluctuations.

c) During the current warranty period, the parts on the spare parts list will be covered free of charge. Shipping costs for these parts must be paid by the buyer.

FACILITY:

Before the shipment of the machinery, the place where the washing line is going to be installed must have the appropriate electricity and water services.

The manufacturer will send a Technical Engineer who will supervise the assembly. For its part, the buyer will provide support personnel (electrician, mechanic, etc.) and sufficient auxiliary labor to carry out the installation of the equipment.

The buyer shall pay the cost of round trip air transportation of the Engineer responsible for the installation, his hotel and living expenses and his fees at the rate of USD 40 (Forty American Dollars) per day during the installation period.

The materials, equipment and labor costs required for the installation are for the account of the buyer.

The factory reserves its right to modify the size and design of the washing line and its components.