Security and Confidence in your investment

– 15 years of experience in machinery manufacturing. The best prices Check it out!!

– In addition to manufacturing, we also recycle and pass on this experience to our customers to reduce the risk at the beginning of the learning curve.

– Financing / Leasing / Months Without Interest / Concession / Compliance Bonds

– Purchase and marketing of the material you produce.

– Get to know some of our developed projects, contact us now.

SHREDDERS FOR EVERYTHING

PLASTICS

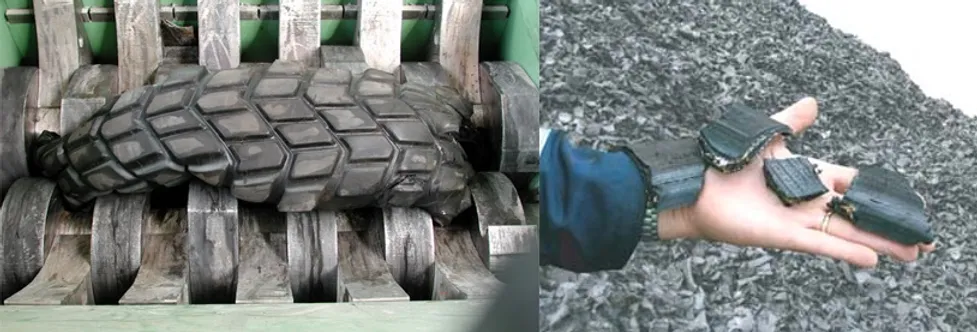

TIRES

STEEL

TEMPERED

PLATFORMS

ALUMINUM

PAPER

ELECTRONICS

VOLUMINOUS

PLASTIC PURGE-STONE

URBAN SOLID WASTE

INDUSTRIAL WASTE

WOOD

TEXTILES

HAZARDOUS WASTE

SHREDDER CHARGES EVERYTHING

MILL FOR PET AND PLASTICS IN GENERAL

CRUSHERS FOR VOLUMETRIC REDUCTION OF VARIOUS MATERIALS

TIRE SHREDDERS

OUR MODELS

Some of our clients

PET

HDPE

PP

AGRICULTURAL PLASTIC

MACHINERY

WE ARE MANUFACTURERS - THE BEST PRICE! COME AND CHECK IT

Model M10

80 - 150 kg/hr

It includes

-

Shipping around Mexico

-

Technical training

-

Purchase of material you produce

-

Monthly financing without interest

-

Confianza cliente pago en contra entrega

Optional Accessories : Improve Performance

SELECTION

FEEDER

EXTRACTOR

SHARPENER

EXTRA BLADES

*Production capacity depends on the type of plastic, flake size, sharpness, adjustment and calibration of blades.

Model M20

180 - 350 kg/hr

It Includes

-

Shipping around Mexico

-

Technical training

-

Purchase of material you produce

-

Monthly financing without interest

-

Confidence customer payment against delivery

Optional Accessories : Improve Performance

SELECTION

FEEDER

EXTRACTOR

GRINDER

EXTRA BLADES

*Production capacity depends on the type of plastic, flake size, sharpness, adjustment and calibration of blades.

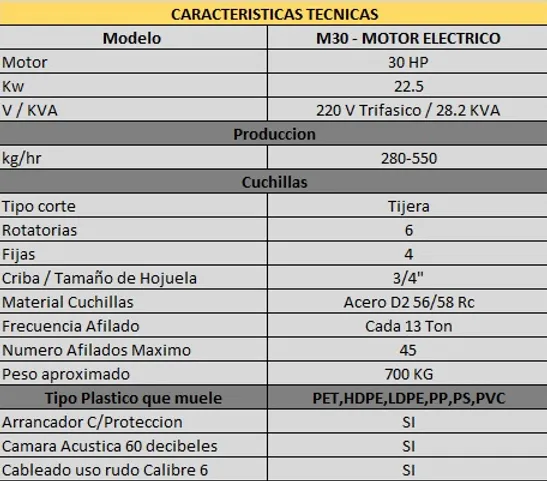

Model M30

280 - 550 kg/hr

It Includes

-

Shipping around Mexico

-

Technical training

-

Purchase of material you produce

-

Monthly financing without interest

-

Confidence customer payment against delivery

Optional Accessories : Improve Performance

SELECTION

FEEDER

EXTRACTOR

GRINDER

EXTRA BLADES

*La capacidad de producción depende del tipo de plástico, tamaño de hojuela, filo, ajuste y calibracion de cuchillas

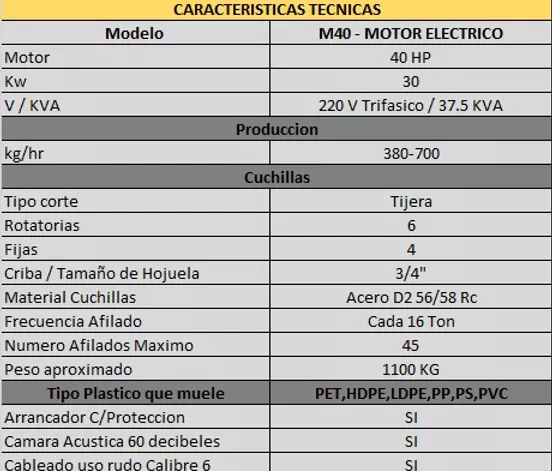

Model M40

380 - 700 kg/hr

It Includes

-

Shipping around Mexico

-

Technical training

-

Purchase of material you produce

-

Monthly financing without interest

-

Confidence customer payment against delivery

Optional Accessories : Improve Performance

SELECTION

FEEDER

EXTRACTOR

GRINDER

EXTRA BLADES

*Production capacity depends on the type of plastic, flake size, sharpness, adjustment and calibration of blades.

DOUBLE SHAFT SHREDDERS

Used for volumetric reduction of various materials:

-

Tires

-

Wood

-

Textiles

-

Aluminium

-

Organics etc

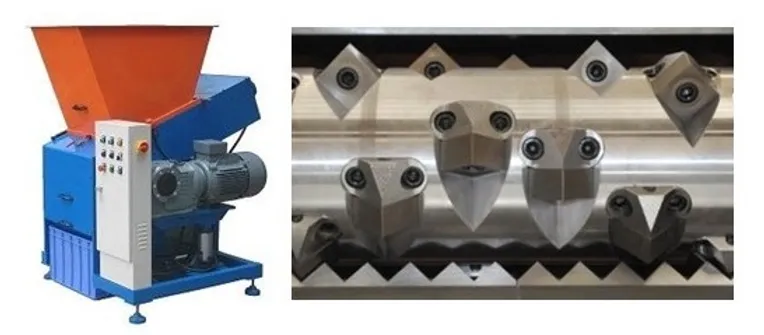

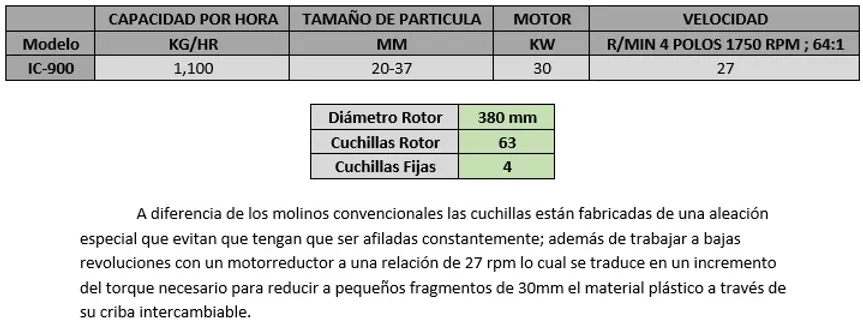

SINGLE SHAFT SHREDDERS

Videos of our machinery

Our equipment is designed to meet the demands required in the national/international market for the reuse/recycling of various plastics commonly used in industries in general (PET, HDPE, LDPE, PP, PS, PVC, PC, PU) in order to guarantee a high added value to your material.

We have a wide variety of grinding equipment and systems manufactured with the highest quality materials to ensure optimal performance, we use world-renowned mechanical and electrical components with which we offer strong and very resistant units.

If you require a machine with greater capacity in the short-medium term, we have the possibility of taking into account the machine that you initially purchased with us, paying only the respective difference, and we will deliver one with greater capacity, according to your needs.

STEPS TO ORDER YOUR GRINDING MILL

1. CONTACT DETAILS

Fill out the attached form in point 4 of this list with the following information:

-Full name

-Mill Model

-Destination place

2. DELIVERY AND PAYMENT

Once we receive your information, we will contact you to confirm the date of departure and delivery of your machine. The payment of the machine is made upon receipt of the equipment (payment on delivery), no deposits or advance payments are requested. If the shipment is within the republic, the equipment is sent through CASTORES cargo transport. The shipment has no cost within the republic to any of the following points where Castores has offices:

Once the equipment arrives at any of the aforementioned destinations, the client is notified so that he can go directly to the transport offices to corroborate and verify in person the arrival of the equipment. Once the shipment of the equipment has been confirmed, in order to be able to deliver the machinery, full payment is required, once confirmed, we send an authorization to the transport companies to be able to deliver the equipment.

3. TRAINING

To be able to schedule the technician's visit for training, it is necessary that the equipment is in the place where it will be fixed and that the necessary means are available for the installation and start-up of the machinery; three-phase light and wiring. For training in the classification of the different types of plastics, it is necessary to have enough material to be able to carry out a practical demonstration of the proper way to select the material and avoid contaminating it by combining plastics from different categories.

In order to schedule the delivery of a load of material, it is necessary for the client to send a sample of their material (2 kg) to the following address: Carretera Federal Mexico Pachuca Km 81, Bodega 1, Pachuca, Hidalgo Once the quality of the material is confirmed according to the parameters and guidelines given during the training, the unit is programmed according to the volume 13 Tons (Torton), 24 Tons (Trailer) for its collection.

WE HAVE IMMEDIATE DELIVERY EQUIPMENT, WE SHIP AT NO COST TO ANY PART OF THE COUNTRY