BLADE SHARPENER

Uses and features:

Designed for sharpening flat blades up to 700mm long. With the capacity to sharpen up to 4 blades simultaneously, allowing substantial savings in time and economy in your workshop.

EXTRACTORS AND CYCLONES:

Due to its design, this system can be easily adapted to the mill, which offers a constant discharge of the granulated material through a silage tube to a container or silo.

POLYETHYLENE COMPACTOR / BINDING MACHINE

Designed for bag processing (film) for recovery and recycling (LDPE, HDPE, PP, LLDPE, BOPP, HM, polyester, nylon, PVC, etc.). Ideal for converting the bag into small clusters of concentrated material in order to facilitate feeding into the extruder.

Description of the operation: The densification process operates by loads, that is, it must be continuously fed in order to be able to create sufficient temperature based on friction to cause the material to concentrate in small particles of agglutinated material, for which it is necessary the action of the water in order to achieve a homogeneous densification.

All our machines are detailed to suit the client, for which we have the flexibility to offer the following options:

– Blades in tempered D2 steel / Imported blades with tempered insert / etc..

– 2 or 4 Blades

– With or without Magnetic Starter

– Blades inside the pot

– Pulleys and Bands

– Color of the machine and logo of your company

– 20, 30 and 40 HP (up to 100 HP)

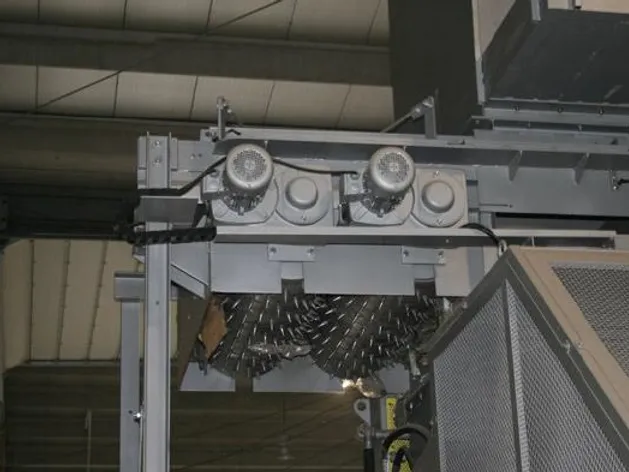

CONTAINER PUNCHING MACHINE

The machine that we present to you below has the function of reducing the volume of plastic containers (squashes them) in this way it optimizes the space, volume and therefore the weight of the bales to increase the production/maquila process. in your business.

PUNCH FOR Pet: It consists of 2 rollers 85cm long, one with 148 spikes and the other with 296, thick caliber. This machine weighs approx. of 450Kg measures 1.40 meters high and 110 cm wide. Traction from Roller to Roller is done by means of Gears and From the Motor to Roller with sprockets and chain.

These punchers have a capacity of 1,800kg per hour.

Punches and crushes the PET bottles, speeding up the manufacturing time of the bales, at the same time it allows to maximize the density or weight of the bale. Increase the weight of your bales by up to 30%

HOPPER DRYER

Designed to treat any type of non-hygroscopic granule thermoplastic material.

The hopper is made of stainless steel and completely insulated with ceramic fiber. They can be installed directly on top of the converting machine or on a stand with wheels. Special attention must be paid to the manufacture of the drying hoppers to favor the homogeneous diffusion of hot air. Hopper cleaning is made easy with the quick opening hinged lid assembly.

The partial or total recycling system of the return air allows optimization of the drying cycle depending on the percentage of moisture in the granule.

DEHUMIDIFYING DRYER

The first step in producing a good quality bottle is the drying of the PET resin. Moisture must be removed prior to injection. We recommend using a dehumidifier, which recycles heat to use energy efficiently and get the dew point of PET to -50oC or lower.

PLASTIC SPRAYER (MILLER)

The sprayers are made for the treatment of small plastic materials and surfaces that are not extremely hard. These pulverizers are used to recover plastic from recycling lines or dispose of waste.

VIBRATORY SIEVE TABLE

-Used to classify diameters in granules

-Inclination can be adjusted according to your requirements.

-Easy replacement of mesh, simple preventive and corrective maintenance.

-Made of stainless steel

-Variable screen diameter, depending on customer requirements.

MAGNETIC SEPARATORS

Designed for the removal of ferrous particles, attachment regularly attached to conveyor belts.

LABEL REMOVER (DE-LABELER)

1. Motor : 18.5kw+5.5kw(water pump)

2. Rotation speed: ≥450rpm

3.Label removal rate: ≧95%

4.Water usage: recycled water

5. Capacity: 600kg/h

6.Material used: carbon steel

7.Dimensions:5000×1800×3400mm(L×W×H)

8. Weight: 3000kg

This machine can remove labels and caps up to 95%

LABEL, FINES AND PAPER SEPARATOR IN GROUND MATERIAL

Used for the separation of small particles such as paper and labels that have not been removed in previous processes such as flotation tanks and/or gravity separation.

VERTICAL CENTRIFUGE

Used for the separation of small particles such as paper and labels that have not been removed in previous processes such as flotation tanks and/or gravity separation.

VERTICAL MIXER

Characteristics and applications:-Used to mix, dry and dye pigments to resins that can be used in extrusion processes, etc.-Heating caused by friction.- After heating, the material is automatically cooled which eliminates the rest of air in order to avoid agglomerate.

HORIZONTAL MIXER

Used to mix, dry and dye pigments to resins that can be used in extrusion processes, etc.-Heating method: Steam and electrical resistance.-Hydraulic and pneumatic opening/closing mechanisms for cooling/heating mechanism.

HIGH SPEED FRICTION WASHER

Used as a complementary module for the washing of material in order to be able to eliminate, through a friction mechanism, contaminants or unwanted material spilled on the ground plastic flakes (PET, PP, PE, PS, ABS). In addition to being used as a means of transport between modules to continue with the recovery cycle.

Technical data:

-Motor: 7.5kw/11kw/22kw

-Screw diameter 300mm/500mm

-Speed: 700-900rpm

-Length: 2500-3500mm

CENTRIFUGAL DEHYDRATOR FOR FILM

-Complementary attachment in recovery lines for plastic film (LDPE) or for hard plastics such as PET flakes, PP or PE. Used to partially remove the water from the wash cycle.

-Made of stainless steel.

Technical data

-Engine:37kw/55kw/75kw

-Speed: 1270rpm/1470rpm

-Capacity: 300kg/hr ,500kg/hr and 1000kg/hr

-Screen: 3mm