-

(477) 873-9338

-

ventas@maquinariaparaplastico.comventas@maquinariaparaplastico.com

-

+52 (477) 873-9338+52 (477) 873-9338

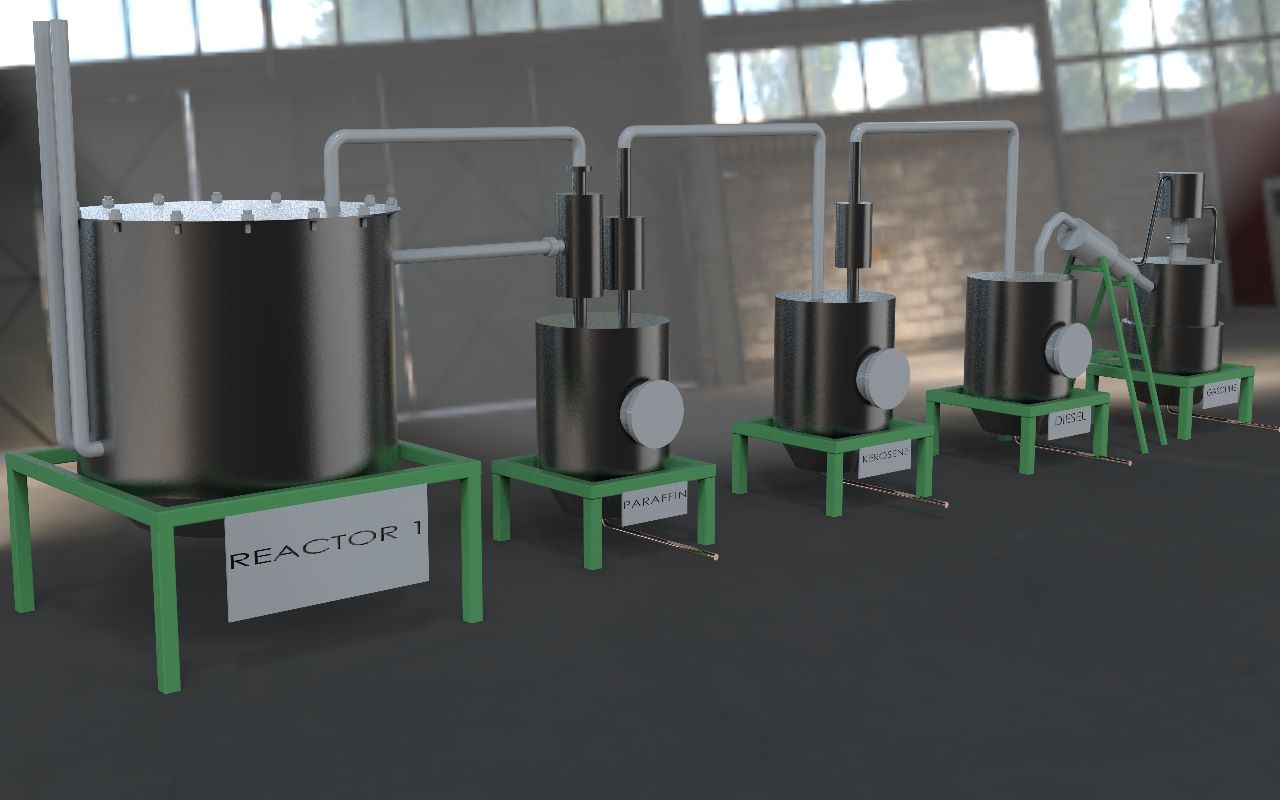

PYROLYSIS

Using Plastic as Energy Source

We at TEVA DISTRIBUIDORA ® want to address the worldwide issue of trash made entirely of plastic. We cleanly recycle plastic into usable fuel, re-establishing ecological harmony around the planet in the process.

Disposing of plastic garbage effectively

A universal solution to the plastic debris issue that lessens the environmental toll of trash and helps nature find its equilibrium again. To combat the universal issue of plastic trash, we must construct plastic-to-fuel transition factories in every region. If you're interested in owning your private Pyrolysis plant, we offer licences for our innovative features.

The plastic to gasoline conversion techniques designed by TEVA DISTRIBUIDORA ®, can be purchased from us, and we will construct a by TEVA DISTRIBUIDORA ® Manufacturing Facility for you. Wherever you are in the world, we will create and construct a plastic landfill conversion plant on your site.

Acquiring gasoline and diesel fuel from plastic trash As its name implies, by TEVA DISTRIBUIDORA pyrolysis Technology is based on the concept of turning plastics into fuel. To compare, diesel fuel only accounts for 28% of the vehicle's fuel needs, while gasoline only

● Gasoline 48%

● Diesel 28%

● Kerosene 14%

● Paraffin 5%

Mechanism of Action

With the help of the TEVA DISTRIBUIDORA Technology, plastic trash may be turned into energy.

PETE

● Polyethylene

● terephthalate

HDPE

● High-density polyethylene

PVC V

● Polyvinyl chloride

LDPE

● Low-density polyethylene

PP

● Polypropylene

PS

● Polystyrene

Mechanism of Action

Condensation, followed by the fuel and vapour combustion, and lastly collection, are the next steps in the project's progression.

The procedure commences with plastic garbage being shredded into small particles or wedges.

Neither any catalyst is needed, and the tiny fraction of LPG extracted can be used to power the next step in the process, allowing the system to maintain itself.

Hydrocarbons are created by adding crude ingredients to the furnace and then regulating the pressure

and distillation temperatures. Other benefits of this setup include:

• No emissions are released

• Multiple plastic kinds can be processed simultaneously

• Closed loop system.

If you're interested in building and owning your own TEVA DISTRIBUIDORA Processing Plant, we'll licence you the technology to do so.

"The plastic to gasoline conversion techniques developed by TEVA DISTRIBUIDORA can be purchased from us, and we will construct a TEVA DISTRIBUIDORA Manufacturing Facility for you"

Anywhere in the world*, we can design and construct a plastic waste conversion plant on your site. In addition to providing 12 months of operating assistance, our construction firm will help you with the campus build out of your plastic waste conversion facility. In 12–24 months**, you will see a return on investment from the time your plant goes into operation.

Establishment for Dealing With Raw Materials

The purchase of one of these plants includes not only a fully operational pyrolysis plant, but also comprehensive safety and training instructions, as well as extensive hands-on instruction.

Constructed with safety in mind, this easy-to-use model requires just a small team to

Plants may process the following amounts of plastic per batch, with output varying from 26,880 to

264,193 gallons per month for gasoline and 15,533 to 166,428 gallons per month for diesel, respectively.

7 tonnes, 14 tonnes, 35 tonnes, and 75 tonnes

Easy-to-understand procedures with a quick return on investment There is no need to hire skilled workers, there is an abundance of raw materials, there is a positive effect on the environment, the process is sustainable, and the plant itself has a long lifespan because it is not exposed to any corrosives.

Find Out How You Can Invest In A pyrolysis Processing Facility Of Your Own

Take the lead in the transition to cleaner fuels. Get the details on licencing our technology so you can construct your own pyrolysis Processing Plant. Contact our company immediately to make an investment in your future. In any case, we hope to begin cooperating with you soon.